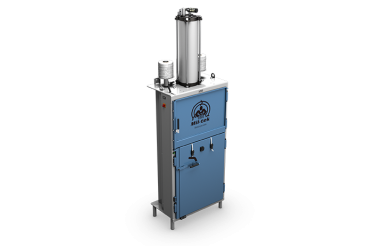

A205 Cardboard & Plastic Baler

The A205 is our fastest and most versatile baler, combining innovative pneumatic technology with a small physical footprint.

- Bale 50 kg cardboard & 120 kg plastic

- Double-acting cylinder with ECODrive

- Floorspace footprint of just 0.45m²

- Worlds’ fastest pressing cycle

- Optimal working height

- EN16500 certified

- Bale size is adjustable