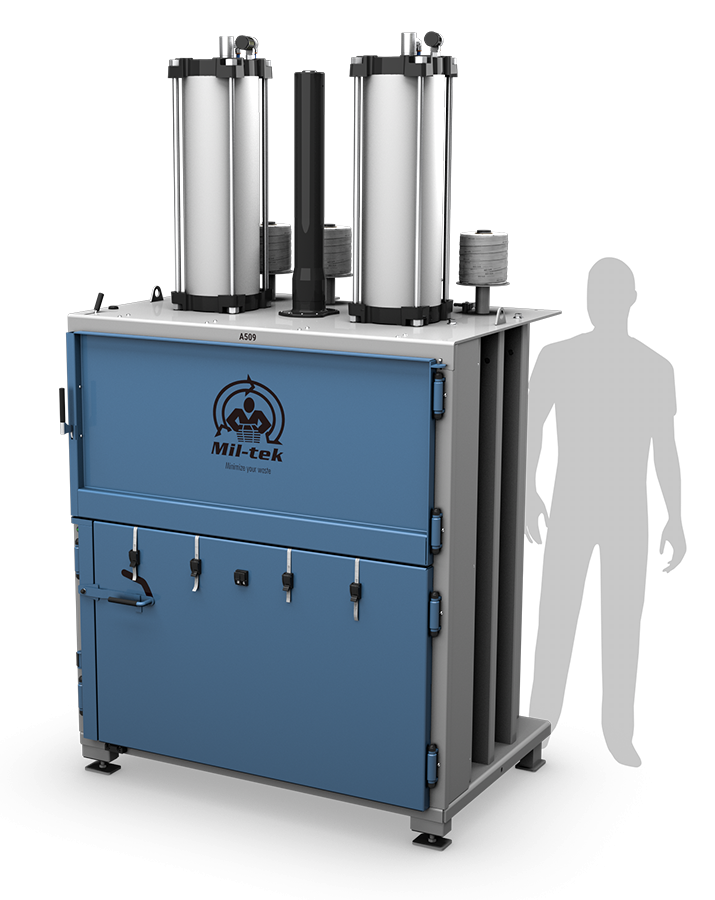

A509 Cardboard & Plastic Baler

1.5m² footprint and lightning-fast pneumatic pressing power. Speed and power are combined in the third-generation A509 cardboard and plastic baler for extremely effective heavy-duty use.

- Bale 225 kg cardboard & and 300 kg plastic

- Dual, double-acting cylinders with ECODrive

- Bale-out indicator & auto bale-out function

- Heavy-duty baler for large waste volumes

- Adjustable bale size

- 1.5m² footprint