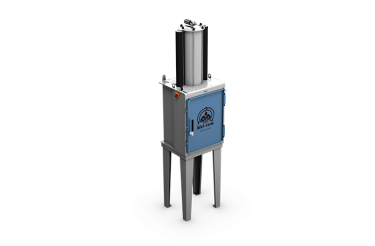

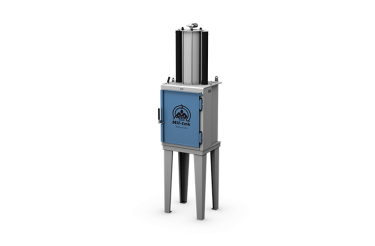

A101 Can Crusher

The Mil-tek A101 Can Crusher reduces volume by 90% by crushing and compacting tins, cans, drums, and buckets up to 30L.

- Crush up to 30 litres of cans, tins, and drums.

- Enhanced operational and safety attributes

- Flammable and nonflammable fluids

- Low on noise, low on energy

- Up to 90% compaction

- Use indoors or out

- Small footprint